A strip foundation for a fence is a continuous strip of concrete, which is poured along the entire length or facade of the future fence. It is considered excellent protection of the structure from deformation.

This base can withstand heavy loads well. If the installation technology is followed, the service life of the structure will be significantly extended. Following the recommendations of the masters, you can make it yourself.

Such a foundation is placed in cases where it is necessary to make a reliable foundation for a heavy fence. These include:

Suitable for areas where it is not possible to equip a deep columnar foundation.

A buried tape will provide a solid foundation on weak soils, while a non-buried tape will provide a solid foundation on hard, stable ground.

Advantages and possible disadvantages

The advantages of such a foundation:

- High strength at low installation depth.

- A high-quality poured solid concrete strip extends the life of the fence for decades.

- If necessary, the base can be reinforced with pipes and metal corners.

- The tape protruding above the ground level is lined with stone, which makes the structure more beautiful.

Photo: 3D model of tape laying

Photo: 3D model of tape laying Among the disadvantages is the large waste of materials, and therefore the high cost of construction. If the construction area is large, you will need to use special equipment and 2-3 assistants.

- Prefabricated. For the arrangement, splitter blocks, artificial or natural stones are used. Installation is simple and reduces time significantly. During construction, slight deviations in size are allowed. It is important that the foundation material is strong and resistant to moisture.

- Monolithic. For heavy structures with high load-bearing capacity. Their creation is labor-intensive, requires experience in construction and high consumption of materials.

- a - made of blocks: 1 - blind area, 2 - backfill with soil.

- b - monolithic: 1 - bulk soil, 2 - monolithic concrete.

- c - brick: 1 - brick foundation, 2 - backfill with soil.

- g - on heaving soils: 1 - sand and gravel mixture, 2 - crushed stone or gravel, 3 - sand cushion.

- I - from blocks

- II - monolithic

- III - made of brick.

Depending on the raw materials used, the tape is distinguished:

- brick;

- reinforced concrete;

- rubble concrete;

- soil-cement;

- stone.

According to the method of deepening into the ground, there are three types:

The width of the future foundation depends on the weight of the fence material for the spans. The heavier it is, the wider the trench should be made. Average– 40 cm.

Thematic material:

Protecting the foundation from excess moisture, providing drainage

Regardless of the type of tape used, in order for it to serve for a long time, it is recommended not to neglect the arrangement of the waterproofing layer.

It is done in two ways:

- Laying roofing felt. A budget-friendly, fast, but not so reliable method of protection against moisture, since after 2-3 years it begins to peel off. This material is used to lay out the bottom of the trench and cover the finished frozen base. For fixation, they are covered with resin or hot bitumen on top.

- By adding a product like Penetron to the concrete solution. This is great protection strip foundation any depth. Its advantage is that the entire base becomes impermeable to moisture. Penetron is added to the solution at the mixing stage. The finished base does not require additional coating with waterproofing material.

If you need to fill the foundation for a fence in areas with high levels groundwater, then you should worry about creating drainage in advance.

A plastic or asbestos-cement pipe with a diameter of 8 to 11 cm is laid in a trench on top of the sand cushion, both edges of which are recommended to be filled with sand. This is done so that when pouring the tape with concrete, the solution does not get into the pipe cavity. Below the base of the foundation, in several places, you will need to dig inspection wells into which water will flow from the pipes during flushing.

If the fence is on a slope, then it is more convenient to make open drainage. That is, dig several ditches connected to each other near the structure.

Step-by-step instructions for creating a strip base for a fence

In order to correctly complete all stages of work, it is recommended to draw up a drawing of the future structure in advance, which will indicate in detail the placement, dimensions of all elements, types of materials and other quantities. The diagram allows you to see what difficulties you will encounter. If errors are detected, they can be corrected at the design stage.

Tools and materials you will need:

- bayonet shovel;

- level;

- wooden pegs and rope;

- boards, plywood, nails and hammer (for formwork);

- cement, sand, crushed stone, water (for solution);

- container and construction mixer for manual mixing or concrete mixer;

- reinforcement bars;

- pillars.

In places where wickets and gates are installed, it is permissible to replace the strip foundation with a columnar one.

Determine the dimensions, choose a location

Before starting construction, it is important not to forget about the SNiP requirements regarding the distance of fences from buildings, nearby areas, and streets. If possible, obtain the consent of your neighbors to avoid conflict situations.

If we talk about the dimensions of the strip foundation (width, height, length), then they are selected individually based on:

- soil type;

- depth of groundwater;

- type of sectional material (whether the load will be large);

- number of gates, wickets.

It is worth performing an accurate calculation of the base area in advance. The following formula will help with this:

(k(n)*F)/(k(c)*R),

where k(n) is the reliability coefficient;

k(c)—working conditions coefficient;

R is soil resistance.

Such data can be found in special tables. If you doubt the accuracy of the calculations, use simplified versions of construction calculators.

Carrying out markings

This initial stage works We clear the site of unnecessary objects, garbage, and vegetation.

A laser level will be an excellent assistant for marking. If this is not the case, then the verticality of the corners will have to be checked with a regular level.

We carry out from the corner of the fence. We drive wooden pegs in these places. Then we install them at the points where the pillars will be installed every 2-2.5 meters. We pull the rope tightly between the pegs.

It is better to make external and internal markings under the tape, not forgetting about the indentation of 40-50 cm.

Preparing the trench

The trench is dug manually with a shovel. It is important to ensure that the bottom is equally level throughout the entire foundation. To do this, we transfer soil from high areas to lower ones so that it does not have to be removed.

We make the width of the tape 20 cm larger than the width of the future fence. We select the depth based on the soil characteristics of the region.

To better distribute the load throughout the structure, we create a sand cushion in the trench. To do this, pour a 10–15 cm layer of sand onto the bottom, level it, moisten it with water and tamp it.

Choosing the right brand of cement

The reliability and durability of the foundation directly depend on the quality and strength of the prepared mortar. Therefore, you should not save on concrete by buying goods from a dubious manufacturer.

- For fencing made of welded mesh, corrugated sheets, picket fences erected on hard soils, grade M 100, 200 is sufficient.

- For heavy fences made of brick, stone, and forged elements, it is worth using cement grade M 250, 300, 400, 500.

On moisture-saturated soils, the required concrete option is M 400 or M 500.

The optimal crushed stone fraction is 20-30. It is better to take quarry sand.

Calculating the amount of concrete

To accurately determine the required volume of solution, it is necessary to multiply the cross-sectional area of the foundation by its length.

To mix a high-quality mixture for 1 cubic meter of concrete you need:

- 340 kg of cement;

- 0.86 cu. m crushed stone;

- 1.05 cu. m of sand.

The amount of reinforcement is calculated from its diameter.

To make the solution harden faster and be resistant to frost, plasticizers are added to the mixture.

We install the formwork

Formwork is a panel structure that provides the strip base with a neat, even and straight shape. For production it is allowed to use pieces of boards and plywood.

The height of the formwork must be greater than the depth of the foundation.

We nail parts of the boards together. We fasten the shields along the perimeter of the trench, securing them with spacers.

Users often search:

Installing pillars

- tree;

- brickwork;

- asbestos-cement, concrete pipes;

- metal profile pipes.

A detailed description of each type and step-by-step installation can be found here:

More often they choose profile pipes with a cross section of 60*60 mm. Before installation, they must be treated with a primer and painted to extend their service life and protect against corrosion.

Under each pillar we dig a hole with a diameter of at least 20 cm and a depth of 1 m. We fill the bottom with a layer of crushed stone and sand. We fix the pipe in the hole. We check the verticality of the installation with a level.

Making trench reinforcement

After fastening the supports, we move on to reinforcement. Rods with a diameter of 8 to 12 mm are suitable for this.

Before laying the frame, it is better to line the bottom of the trench with a layer of brick.

The reinforced structure consists of 4 long longitudinal rods that are connected by transversely located jumpers. Medium size cells - 33*35 cm. For jumpers, rods of smaller diameter are always taken. The number and diameter of the elements are determined when developing the drawing of the future fence.

The depth of laying the upper and lower levels of reinforcement is 10 cm from the top edge and, accordingly, from the bottom of the trench. There should also be protrusions of 5 cm on each side. They are necessary for ease of installation inside the trench.

Filling the tape

Performed in 2 ways:

- Continuously. When filling a small area.

- With a technological break. Used for laying foundations for long fences. We pour concrete in layers of 20 cm. We tamp each layer. Fill the next one after the previous one has dried.

We remove the formwork after the tape has completely hardened. In the warm season, 7 is enough for this. – 10 days, in cold weather you will have to wait up to a month. We treat the finished base with hot bitumen. We backfill the soil.

When is it necessary to cover the foundation?

When erecting a stone, brick, or wrought-iron fence, the strip protruding above ground level becomes part of the structure, therefore, in order for the fence to have a complete look, its lower part is finished. The following materials are suitable:

In order to save money, you should not use such a technique as painting on a concrete surface. This will cause the solution to crack.

Monolithic tape is a reliable basis for the fence, which will give it neatness and extend its service life by years.

Today, fencing made from corrugated sheets is almost the most common, due to its relatively simple installation, durability, aesthetics and variety of colors and shapes. Sheets are made from galvanized steel by cold rolling and painted. The sheet sizes vary from manufacturer to manufacturer. The most common one has a width of 1150 mm, a useful width of 1100 mm, since it is mounted “overlapping”. For fences, regular corrugated sheeting marked C10 and more rigid C21 are used, but the main thing is to choose the right foundation under a fence made of corrugated board.

A strong foundation is the key to the long “life” of any fence

Types of foundation for a fence

The main factors when choosing a foundation are:

Groundwater level in the work area. The closer they are to the surface, the more thoroughly they will have to build.

Calculation of the “windage” of sheets.

Soil type. The softer and wetter the soil, the deeper the foundation needs to be laid.

Availability of nearby busy highways and railways. Heavy vehicles cause vibrations in the soil, causing the fence to collapse.

It’s just that the pillars driven into the ground will very soon go “downhill”

There are several types of foundation:

Columnar. This is the simplest and easiest type to perform. Its essence is that holes of the required depth are made with a hole drill, into which the vertical supports of the fence are driven and the cavity is concreted.

Tape. When constructing a foundation, a trench is dug, the cavity is reinforced, vertical supports are installed, and it is filled with concrete.

Ribbon-columnar. This is a combined type of foundation in which a trench is dug between the pillars and poured with concrete after reinforcement. The pillars can be either monolithic or made of brick or cinder block. For greater aesthetics, it can be finished with facing stone.

Stone. The most expensive and labor-intensive type of fence, but the most reliable. The foundation is laid out from rubble stone and filled with concrete, having previously inserted supports. You can also lay out the columns of the future fence from stone.

The most common, reliable and durable fence is rightfully considered to be a fence made of corrugated sheets on a strip foundation. It is the strip foundation that is most suitable for this fence.

The strip foundation will not only serve for a long time, but will also prevent runoff from pouring into the yard after rain and snow.

On our website you can find contacts construction companies who offer fence construction services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Stages of strip foundation construction and fence installation

Marking and digging a trench

The first step is to mark the location of the fence so that it does not extend beyond your land plot, since after installing the foundation it will be problematic to move it.

To mark the perimeter, pegs are hammered in and strong twine is pulled. Next, you need to remove plants and shrubs along the entire length. After this, the installation locations of the pillars are determined. To do this, use a tape measure to measure equal distances from the corners, depending on the factors mentioned above. It is necessary to take into account the length of the gate and wicket.

Next, a trench is dug 30-40 cm wide and 70-80 cm deep from the ground surface. This is done using a narrow-bucket excavator or manually. It all depends on the type of soil and the desired speed of construction. In the presence of rocky soils, a hydraulic hammer is used or, in the manual version, a jackhammer is used. In this case, the depth of trenches in such hard rocks can be reduced.

Then a sand “pillow” is made in a layer of 10-20 cm. It must be compacted. It will serve as the base of our foundation and provide the necessary drainage.

If the terrain is uneven, it should be taken into account that one section of the fence should be at the same level. In such cases, the fence is made in “steps”.

One of the ways to plan fence architecture for uneven landscapes

Installation of formwork

When arranging the formwork, its assembly is carried out 20-30 cm above the ground surface. It can be made from boards, metal sheets, plywood or professional formwork plywood, which will allow it to be separated without much difficulty when the concrete dries.

Uneven terrain adds difficulty in installing formwork to make a foundation for a corrugated fence. Since one section will have one elevation, it is necessary to install the formwork at the planned height. The sections in this case are separated from each other using the same formwork. In this case, each compartment will subsequently be filled with concrete in stages. Naturally, the reinforcement of concrete will be somewhat more complicated than with a flat surface.

Assembly of formwork and reinforcement for the future foundation

Installation of supports and reinforcement

The next stage is to install vertical supports for the future fence. Usually a steel corner or a square profile of 30-40 mm is selected. To increase the service life, supports and longitudinal joists must be primed and painted, having previously cleaned out pockets of corrosion, if any.

Video description

The fence supports can also be as shown in this video:

The supports are driven into a trench at a distance of 2 - 3 meters and to a depth of at least 20-30 cm. If there are rocks, a hole is hollowed out under each support, which, after installing the support, is either separately concreted or filled with soil and compacted. In this case, it is necessary to install supports to ensure their verticality before pouring concrete. The distance between the supports is selected depending on the area of work and the height of the fence itself. Usually it is 2.5 - 3 meters. In windy areas, such a fence acts like a sail, and with large lengths there will be a high probability that the sheets will be deformed or even torn off from their fastening points.

To increase reliability, reinforcement with a diameter of 10 mm is welded between the supports in the trench. At great depths, several such connecting connections should be made at different levels.

Reinforcement is also performed using 8-12 mm reinforcement. Since the foundation bears virtually no load except lateral, no special approach is required. It is mainly required to ensure the integrity of the structure. Segments of reinforcement are driven between the supports and 2-4 rows of reinforcement are tied along with knitting wire, depending on the depth of the trench. For even greater reinforcement, crossbars are applied. It must be taken into account that the reinforcement should be at a distance of 2-3 cm from the edge of the formwork.

Reinforcing rods should not touch the formwork boards

Concrete work: foundation settling and formwork removal

Next, you need to fill the trench to the required formwork level with concrete or mortar using cement grade of at least 200. The strip foundation for a fence made of corrugated sheets is poured in layers to ensure the release of air bubbles from the mortar. As the concrete dries, it is necessary to water it with water. During the first two to three days, it is advisable to do this every 3-4 hours. Watering will prevent cracks from appearing. Then you can do it less often. The demoulding of the foundation is carried out depending on temperature conditions when the concrete reaches 70% strength, which takes 2-4 days. When using additives that accelerate hardening, it is possible to remove the formwork even after 24 hours. However, installation of the fence should begin no earlier than 7 days.

Installation of longitudinal profiles and fastening of corrugated sheets

This stage involves welding the profiles between the fence supports. It can be made either from a 2-3 cm corner or from a “U” shaped or square profile. Several connection types are used, as shown in the figure. If painting is not done first, then after welding it is necessary to paint the frame of the future fence. Especially when painting, you should pay attention to welds, since this is where corrosion most often occurs.

Fastening the corrugated sheets in relation to the pillars is done in three ways

After this, the corrugated sheeting is installed using self-tapping screws with rubber gaskets to avoid damage to the sheets and rust at the fastening points. The distance between the fasteners depends on the size of the sheet.

To improve the appearance, the foundation can be finished with tiles, facing bricks or stone, simply plastered and painted.

Video description

For an overview of the process of creating a foundation and installing a mono fence, watch the video:

Common mistakes during construction

Insufficient foundation depth, as a result of which the fence can “float”, warp and burst. This is especially true for wetlands with close groundwater (near reservoirs, ponds, etc.).

Conclusion

The same consequences can occur if the layer of sand or gravel cushion under the foundation is insufficient or was poorly compacted. And, of course, poor-quality reinforcement can lead to cracks and chips of concrete. In general, we can say that the preparatory stage, before pouring concrete, can be considered the main one in the construction of a high-quality fence.Building a fence around local area, every owner dreams of making it as durable, aesthetic and durable as possible. Fences that have a foundation strip at their base most closely meet all of the above requests. However, the average consumer involuntarily has a question: what is the right thing to do, entrust the installation to a team of professionals or make the foundation for the fence with your own hands? After all, the service life and external attractiveness of the entire structure depend on the quality of the foundation pouring work. Of course, doing it yourself allows you to save a significant part. cash, but not everyone knows how to properly pour a foundation. Therefore, before starting construction, you should carefully study what the foundation for a fence can be and the basic rules for its installation.

Which foundation to choose?

Today, the most popular fence is one built on

- strip base;

- columnar foundation;

- strip-column base.

Scheme strip base

The construction of any of them can be done independently without the use of expensive equipment and experience in in this direction. Indeed, to achieve a positive result, it is necessary to understand the technological process and carry out high-quality preparatory measures.

Columnar structure diagram

Design selection

- Under heavy fences made of natural stone, cinder block, brick, a strip foundation is required, which allows you to evenly distribute the load of the building material on the base.

- A do-it-yourself columnar foundation for a fence requires minimal money and labor costs, is easy to implement, but is only suitable for lightweight structures made of boards, polycarbonate, corrugated sheets, metal gratings or slate.

- Making a fence on a strip-column foundation is an ideal solution in cases where there is a need to completely hide the view from prying eyes in the lower part of the structure. Brick, forged or cast iron sections, corrugated sheets, and polycarbonate are used as the main material for the fence.

Strip-column foundation

A lined foundation looks much more attractive and noble. To create a harmonious ensemble in landscape design, the cladding of the fence is selected in the same style as the existing structures.

Soil structure

The type of soil foundation at the work site is also important. Soil subsidence, erosion by groundwater and soil heaving cause considerable difficulties during installation. Therefore, before making a foundation for a fence, you should get general information about the characteristics of the territory. In some cases, it is enough to communicate with neighbors from adjacent areas and pay attention to how they behave during operation. engineering structures in this area.

The presence of a busy highway or railway also affects the integrity of buildings. In such cases, surface vibrations due to heavy traffic should be taken into account.

Strip-column foundation and its calculation

The strip-column foundation is the best option for construction on the front side of the site. It is able to cope with the weight of almost any materials used in the construction of the fence. It has excellent aesthetic characteristics; if necessary, gray concrete can be hidden by cladding, and metal poles brick finish. You can build such a structure yourself without involving a team of specialists.

Before pouring the foundation for the fence, it is necessary to carry out a number of calculations , to determine in advance the required quantity building materials.

Calculation of burial depth

The depth of the lower boundary of the foundation strip must be below the soil freezing level. This condition should be observed to prevent movement of the foundation during seasonal movements of the earth layers. Heaving soils can damage the integrity of the entire structure, after which repairs to the foundation will be required.

The depth of soil freezing is different for each region and depends on the type of soil and possible negative temperatures. Thus, loams and clayey soils freeze to a shallower depth than sandy soils. All nominal parameters can be viewed in SP 131.13330.2012 BUILDING CLIMATOLOGY.

The construction of shallow foundations is permissible only on homogeneous, subsidence-resistant soils that are absolutely not susceptible to heaving.

In places where the freezing depth reaches significant levels, it makes sense to install pile foundations under fences.

Fence on stilts

Calculation of building materials

- h - height. It is composed of the depth of the foundation for the fence + the desired height above the ground surface;

- b - width depends on the weight of the materials used for the fence.

- a is the length. In fact.

Of course you can buy required quantity ready-made concrete, or you can prepare it yourself using:

- Cement.

- Sand.

- Crushed stone.

- Water.

In a proportional ratio of 1:2:4 (cement, sand, crushed stone).

More often individual construction involves the use of crushed stone of various fractions. To calculate the ratio as accurately as possible, you can use simple method. Pour crushed stone into a bucket, and then pour in water until it fills all the existing voids. The volume of water poured will correspond to the amount of sand required per bucket of crushed stone.

The quality of cement is also important. It is important to consider the period of its production and preliminary storage conditions.

It is unlikely that making concrete at home can compare in terms of technical characteristics with the factory process. It is usually less hard and prone to corrosion; to increase quality, a portable construction vibrator should be used for shrinkage during the pouring process. If it is absent, you can bayonet the concrete mixture with a piece of reinforcement after pouring the mixture.

Calculation of reinforcement for the frame

To increase the strength of the entire structure, the foundation for the fence is reinforced. For a strip base, a design of 4 horizontal ribbed rods (2 upper and 2 lower) and transverse jumpers to form cells connected to each other by knitting wire is sufficient. The spacing of the jumpers is from 30 to 50 cm. In some cases, with a significant freezing depth, the number of horizontal stripes is increased, placing them at a distance of 50 cm from each other.

Reinforcement options for further calculations

It is almost impossible to accurately calculate the foundation, therefore, as a rule, , 10% is added to the obtained approximate result for reliability.

Work order

Construction of the foundation for the fence begins with marking the area and digging a trench for filling. For convenience, the edges of the pit are limited by pegs, between which strong twine is pulled. The distance between the walls of the trench is equal to the width of the foundation + the thickness of the formwork.

In clayey or rocky soils, concrete can be poured directly into the trench, and the formwork is installed only above the ground surface.

They begin to select soil from the lowest point on the site.

If the ground has a significant slope, it makes sense to mount the fence on a foundation located in steps above the ground surface. This will significantly save the amount of concrete used.

- On highly heaving soils, 10–15 cm of sand is poured at the bottom of the trench, which serves as an anti-heaving layer. In places with high groundwater levels, a sand cushion is not made, because over time it silts up and becomes a heaving base.

- Formwork is assembled from edged boards or moisture-resistant plywood. Liquid concrete for the foundation of a fence has an impressive mass and can destroy the integrity of the formwork. To avoid this, a number of strengthening measures should be taken: install slopes on the outside, and also pull the walls together in the upper part, ensuring their vertical position.

- The walls of the formwork for the fence foundation are treated with waste oil so that once concreting is completed, they can be dismantled without effort.

- Install the pillars in accordance with the markings and fix them in a vertical position.

- Reinforcing elements are installed.

- Concrete is poured.

- Concrete can be poured only at positive temperatures necessary for setting and hardening. In hot weather, it is covered with polyethylene and periodically moistened with water to prevent rapid evaporation of moisture from the mixture.

- Remove the formwork. Backfill is carried out and the foundation is left to gain strength.

Having figured out what foundations for fences exist, how to make the formwork correctly, and what concrete to choose, you can start pouring the foundation for the fence with your own hands. If desired, after completing the main work, cladding with decorative materials is carried out. Below is a very useful video that can also be used for fences.

Almost all owners of personal plots sooner or later face the problem of installing a fence. But no matter what it is - light or heavy, in any case, in order for the structure to be reliable and serve properly for a long time, it is necessary to construct a foundation.

Peculiarities

The foundation is the main load-bearing part of the fence. The service life of the entire enclosing structure depends on how correctly its type is chosen and how well it is made. If the foundation is weak or does not exist at all, then the fence may sway, it may move during soil heaving during the spring thawing of the soil, or it may even fall.

What is it for?

The foundation for a fence performs several important functions:

- ensures the stability of the entire fence structure;

- allows you to evenly distribute the load on the fence structure;

- if there is a foundation, the soil lingers on the site and is not washed out of it by water during rain or melting snow;

- serves as a barrier to the penetration of melt water into the area;

- With a foundation, the fence looks much more aesthetically pleasing and reliable.

Is it necessary to do it?

Despite the important functions listed above that the foundation performs, when building a fence, many owners of personal plots, calculating their costs, still think about whether it is worth making a foundation for the fence. It all depends on what type of fence you decide to install on the site.

If this is a lightweight, ventilated structure made from a chain-link mesh or a wooden picket fence, then it is quite possible to get by with concreting only the supports themselves. But at the same time, you need to remember that even for light fences this is not the most reliable foundation, and such a fence will last at most 5-7 years.

If you decide to make a fence that is more solid and durable, then you cannot do without a foundation that matches its weight.

Types of base

The most common option for constructing a foundation for a fence is a strip foundation. It is most suitable for constructing stone fences or fences with stone pillars, between which a fence made of corrugated sheets, forging, wood and other materials is fixed. The concrete base of such a foundation allows the load to be evenly distributed. A strip foundation is suitable for installing metal supports in it followed by attaching fencing structures to them.

To construct this type of foundation, a trench is first dug to the calculated depth and width, at the bottom of which a cushion of crushed stone and sand is placed. Formwork up to 30 cm high is placed above the trench. Pillars are installed inside the trench and reinforcement is laid. Next, the foundation is poured with concrete.

The concrete pouring process is sometimes replaced by laying precast concrete blocks. They are installed close to each other and only the seams between them are filled with concrete.

The most cost-effective option for constructing a foundation for fence supports is a columnar foundation. This type of base is most suitable for heaving soils. Metal or asbestos pillars, brickwork on a concrete base or screw piles. The distance between supports is usually 1.5-2 m.

Depending on the type of soil and climatic conditions a hole for the supports is dug 1-1.5 m deep. A cushion of crushed stone and sand is placed at the bottom and compacted. Next, install the pillars, fix them vertically and fill the hole with concrete.

A universal option is a combined foundation, which is a combination of the two previous types of concrete foundations.

This type of foundation is used for constructing fences made of concrete slabs, forging, and corrugated sheets, especially in the presence of brick pillars. To install a columnar strip foundation, first dig a trench about 0.5 m deep.

In it, holes are drilled in marked places with a depth exceeding the freezing depth of the soil. Next, formwork is installed in the trench, a mixture of sand and crushed stone is poured, and reinforcement is installed. After this, the foundation is poured with concrete.

For various types of fencing

The type of fencing is one of the main factors that determines what the foundation should be like.

For fences made of corrugated sheets, forged elements, mesh, and wooden picket fences, two types of foundations are used. The first option is when the foundation is made for each support (columnar). To do this, a hole is dug in the soil. A pillar is buried in it, and the space around it is filled with concrete.

The second option is a strip foundation, which is a trench dug in the ground into which supports are installed at a certain step and filled with concrete mixture. This foundation design is used when the pillars are located at a fairly short distance from each other.

The strip type of foundation is also arranged when stone or brickwork is supposed to be installed in the lower part of the fence. In this case, the concrete foundation serves as a kind of foundation separating the masonry from the soil surface.

Separately, it should be noted that if you plan to install a fence made of corrugated board with a height of up to 1.2 m, then you can completely get by with pouring a columnar foundation. If the height of the profiled sheet is over 1.2 m, a strip foundation will have to be poured. Since this material is characterized by increased windage, in a strong wind the columnar foundation may simply not withstand the load, and the supports may tilt or even fall.

If you plan to make a fence with brick pillars, then the foundation for it should be quite serious. Such fences are very sensitive to uneven shrinkage. In pillars made of brick, stone or blocks, a mortgage is usually installed, connected to the crossbars of the entire enclosing structure.

If uneven shrinkage occurs, cracks may appear at the junction of the crossbars and the mortgage. To minimize such phenomena, the foundation for such fences is built quite deep, always below the soil freezing level.

Bookmark depth

Another important factor that determines the reliability and durability of a fence structure is the depth of the foundation.

For lightweight fences, the most optimal depth is considered to be 50-60 cm. With such a depth of laying the foundation, the required reliability of the structure is ensured, as well as economical consumption of building materials. But if a light fence is installed on stone pillars and there is above-ground masonry between them, then the foundation can be raised slightly.

With heavier structures the situation is more complicated. When building a foundation for them, one cannot fail to take into account, in addition to weight, the structure of the soil and the depth of its freezing in a given area.

The lower level of the foundation should be located 40 cm below the freezing depth. To clarify this mark, you can use construction reference books.

If a massive fence structure is being built on soft soils in which groundwater runs quite high, it is better to play it safe and lay the foundation deeper to prevent deformation of the structure due to severe subsidence of the soil. A higher foundation location is possible on hard soils. The foundation on shale soils can be constructed at a depth of no more than 25 cm.

Manufacturing

Making a foundation for a fence with your own hands is not difficult. You just need to make all the necessary calculations in advance and strictly adhere to step by step instructions when performing work.

Calculation

To calculate at what depth it is necessary to lay the foundation for medium-heavy and heavy fences, it is necessary to take into account the following factors: the design features of the fence, the depth of soil freezing, the slope of the terrain, the structure of the soil and the height of the groundwater.

In order for the calculation to be correct, it is necessary to calculate the area of the foundation. So, if we have a foundation 50 meters long and an estimated width of 30 cm, then we can easily determine its area (15 m2), which will later become the basis for calculating the depth of the foundation.

In addition, it is necessary to determine the reliable area of the foundation, which is determined by dividing the pressure of the above-ground part of the foundation, adjusted by the safety factor, by the soil resistance and the operating conditions factor.

The resulting value must be compared with the estimated area of the foundation. The latter must be no less than the calculated value, otherwise it must be adjusted.

Fill

On heaving clay soils, it is best to use a combined type of foundation. Before you pour columnar strip foundation under the fence, you must first dig a trench corresponding to the calculated depth and width. In the places where the pillars are installed, drill holes for installing the pillars.

Next, wooden formwork is installed along the entire perimeter of the future base of the fence. At the bottom of each hole under the pillars, roofing material folded in two layers is placed. Next, the pillars are installed and the foundation strip is reinforced with a mesh of reinforcement.

Now you can start pouring concrete. The correct way to fill it is in horizontal layers. If it is not possible to fill the entire strip at one time, then you should not allow the formwork to be filled to the top in one place, and not be there at all in another. The concrete will take 3-5 days to dry.

If it is hot outside, the foundation must be watered. The formwork is removed from the tape after 2-3 weeks.

Tape shallow foundation make it even easier. It is laid above the freezing level of the soil. Therefore, such a foundation is susceptible to seasonal ground movements. Such a base is more suitable for installation in areas where the soil has a uniform structure over the entire area of the fence.

To construct such a foundation, dig a shallow trench (0.5-0.7 m), at the bottom of which sand (0.15 m) is placed and compacted. A layer of crushed stone (0.15 m) is poured on top. Crushed stone and sand are a kind of drainage base, thanks to which water will be drained from the foundation. Next, holes for pillars with a depth of 0.3-0.4 m are drilled in the trench.

Sand (0.1 m) is poured into each hole for drainage. Supports are inserted into the holes and aligned in all planes.

Next, the pillars are connected with reinforcement using welding. Install the formwork. After this, they begin pouring concrete, adhering to general rules described above. After the concrete is poured, be sure to once again make sure that the pillars are level.

There is another one alternative option foundation devices - from old car tires. But it is quite controversial and is not widely used in constructing foundations for fence structures.

In order for the foundation under the fence to last for a long time, it is necessary not only to fill it correctly, but also to protect it from precipitation. And for this it is necessary to make a blind area or ebb, which is a threshold running along the entire perimeter of the foundation with a slope in the direction opposite to the foundation base.

Casting can be done either simultaneously with pouring the foundation or after. To do this, a trench is dug along the entire fence line to a width of about 0.5 m and a depth of 0.15 m, which is filled with crushed stone and compacted. When the casting is carried out simultaneously with the foundation, reinforcement bars are released from it towards the blind area. If the casting is done after installing the base of the fence, then holes are made in it and reinforcement rods are inserted into them.

Film roofing felt is placed under the reinforcement and formwork is made. After this, concrete is poured, and always with a slope.

On a site with a slope

If it is necessary to build fence structures on a site with a large slope, then the foundation under it should not be inclined. In such cases, a stepped base is built, each section of which is strictly horizontal. In the lowest place, the foundation is made level with the soil. The transition from level to level is made by ledges. The length of the ledges should be no less than 2 times their height. The height must be at least 0.6 m.

If the site has a slight slope, then, as a rule, the soil is leveled along the entire perimeter of the fence structure or a concrete base is installed.

What to paint with?

To improve appearance concrete foundation, you can apply decorative plaster on it by spraying with special textured plaster or colored mortar using a regular broom.

The base under the fence can also be painted with special paints for concrete. You can also find colorful edging or border coverings at hardware stores. Acrylic, latex, epoxy, polyurethane, and alkyd compounds can be used to paint concrete bases.

Acrylic paint is made on a water basis with the addition of acrylic dyes. Due to the presence of copolymers in their composition, it creates a polymer layer on concrete surfaces that protects the foundation from the effects of environmental factors. This paint is easy to apply, dries quickly and is economical in consumption.

Latex paint is made up of water, pigments and polymers. Sometimes it may contain silicone or acrylic resins. This paint can be applied to the concrete base immediately after it has hardened.

The advantage of latex paints is increased resistance to temperature changes, the ability to fill even small cracks, moisture resistance, and economical consumption.

Epoxy compounds are considered the most durable foundation paints. They can protect a concrete base for almost a quarter of a century. The paint consists of two components - epoxy resin and a special hardener, which are mixed immediately before application. The composition is applied in two layers. Epoxy coatings are vapor permeable, which is very important for concrete bases, and are resistant to exposure to the sun, acids and alkalis.

Polyurethane paint also consists of two components that must be combined immediately before applying the paint composition. The paint is applied in two layers. The advantage of polyurethane paints is that they improve the properties of concrete, are frost-resistant, form a protective coating, and close microscopic cracks and pores in concrete.

Alkyd paints are made from alkyd resin. They have a rich palette, dry quickly, are resistant to sunlight, frost-resistant, and are economical in consumption.

But before choosing one or another product, you need to pay attention to whether it is suitable for a given climate. Paint should only be applied to a dry and free of dirt concrete base.

Is waterproofing necessary?

There are two ways to waterproof the foundation:

- A layer of polyethylene or roofing felt is placed at the bottom of the trench on top of the laid crushed stone, which will protect the concrete from moisture, which will increase the service life of the fence base.

- The second method is to use special waterproofing materials that are added directly to the concrete. One such additive is Penetron. When using this composition, the entire volume of the foundation becomes resistant to moisture penetration. Moreover, concrete retains this property throughout its entire service life.

Experienced builders advise adhering to certain rules when laying a foundation for a fence:

- You can begin to build a foundation for a fence only when the type of soil, the depth of its freezing, the type of fence structure, its dimensions have been precisely determined and, accordingly, the range of possible risks has been determined. If any question remains unclear, it is better to seek advice from a professional so as not to encounter difficulties later;

- If the calculation turns out that the load on the concrete foundation is quite significant, then it is better to make a full-fledged strip foundation instead of a grillage, which is located almost on the surface of the soil between deeply laid piles;

- When preparing a concrete mixture, do not use broken bricks, expanded clay or wood. All these materials are capable of absorbing water and after a certain time they will simply rot, and the strength of the foundation structure will significantly decrease;

- The solution for pouring the base under the fence is prepared from sand and cement in a ratio of 3 to 1. First, you should combine the cement and sand, and only then add water, continuing the mixing process. The solution should have a fairly thick consistency and not contain lumps;

- Since the foundation must be poured along the entire perimeter at once (that is, a fairly large volume of mortar will be needed at once), it is better to prepare the concrete mixture in a concrete mixer or order the ready-made mortar to be delivered;

- To increase the strength characteristics of the base, granite chips or crushed stone can be added to the solution under the fence;

- When pouring a foundation in cold weather, special concrete additives should be used to prevent the solution from freezing.

When deciding to build a fence, you should think in advance about the need for a foundation for it. For massive permanent structures it is mandatory, but to get reliable foundation For a fence, it is important to consider many factors.

In this article we will look at which bases are suitable for different fences, how they are made and more.

A high-quality foundation is a guarantee long term service of the entire structure, protection from the negative influences of the external environment.

It is needed to support the fence, give the structure stability and rigidity.

Functions performed:

- Uniform load distribution along the entire length of the fence. Due to this, even over time, the fence will not begin to sag.

- Protection against soil erosion and flooding. The base prevents the soil from being washed out from under the fence, and when the snow melts in the spring, it retains water and prevents it from getting under the structure.

- Maintenance of the structure. The foundation protects against deformation, subsidence, and premature damage to pillars or materials.

- Adding aesthetics. A fence with a base looks neater and more beautiful.

In order for the fence to last as long as possible without the need for repairs, it is necessary to give it a solid foundation.

What to consider when choosing a foundation

There are several key factors:

- features of the site's topography and type of soil;

- depth, groundwater level;

- the presence of a reservoir or underground sources nearby;

- the weight of the future fence;

- how far is the road, railway;

- expected level of soil subsidence during temperature and humidity changes.

It will be useful to talk with the owners of neighboring plots who have already managed to erect a fence, find out real situation, get practical recommendations.

Which fences do not require a base?

This stage of work is not necessary if the fence is installed temporarily: to outline the boundaries construction sites, during repairs or if in the future it is planned to install a massive permanent fence at this place.

Many types of lightweight fences are erected without a foundation, for example, from chain-link mesh, welded products, wooden boards, picket fences, and corrugated sheets. The pillars are simply driven into the soil, compacted or partially concreted.

Butting supports performs well on heaving soils with a high groundwater level. In spring and winter they are not squeezed out of the ground.

Article:

Article: Types of foundations suitable for fences

Tape

Suitable for installation on sandy, swampy, unstable soils. Prevents displacement and deformation of the structure.

It should be used under fences made of brick, wood, stone, corrugated sheets, forged structures, and blocks.

Photo: finished formwork with reinforcement and guides for bricklaying

Photo: finished formwork with reinforcement and guides for bricklaying The thickness of the tape is selected based on the fence material. For wooden sections made of corrugated board, an indicator of 50 cm is enough. Under brickwork, forged or welded spans increase the thickness to 80–100 cm.

This is done along the entire length of the future structure.

Among the advantages are noted:

- high strength, and therefore durability;

- reliability;

- the possibility of reinforcement with reinforcement cages and pipes, which gives the supports more stability;

- you can do all the work yourself;

- no need to use special equipment.

The obvious disadvantage is the high consumption of materials, in particular concrete, which leads to an increase in construction costs.

Installation diagram of a metal profile fence on a strip foundation.

Installation diagram of a metal profile fence on a strip foundation. There are several types of tape:

- Made of reinforced concrete. Suitable for sandy soils. Formwork is erected along the perimeter of the prepared trench. A metal frame is assembled from wire, which serves as reinforcement. Place it in a trench and fill it to the top with a mixture of cement, sand, and crushed stone.

- Made from rubble concrete. Used on rocky soils. The technology is similar to the first type, with the exception of the use of large stones and cobblestones.

- Made of brick. You need to take a solid ceramic or fireclay type. White silicate will not work because it will quickly crumble under the influence of moisture. Otherwise, the procedure is similar to the previous types.

Reinforced tape is much more reliable and durable than just concrete. Wire rods increase the adhesion of the material and resistance to external influences.

Thematic material:

- Self-construction of a strip foundation for a gazebo

Columnar

Columnar diagram

Columnar diagram Designed for lightweight fencing made of:

- profiled sheet;

- polycarbonate;

- metal mesh (chain-link, welded);

- wooden boards, picket fence;

- siding.

This is the optimal type of foundation for heaving soils.

It differs from tape in that you do not need to dig a trench. Each support is individually fixed in the soil.

An important condition is that the depth must be below the freezing level of the ground.

Advantage - minimum consumption materials, which reduces construction costs.

It is convenient to make holes for posts using a garden drill. If this is not the case, you can take a bayonet shovel. The depth is determined by the terrain features of the site and ranges from 1 to 1.5 m. The hole should be at least 20 cm larger than the diameter of the pillar. The pitch between the supports depends on the width of the span, but often does not exceed 2–2.5 m.

The further installation procedure for poles made of different materials may differ slightly.

For brick ones, it is the most labor-intensive. A metal pipe is placed in the center of the pit and lined with brick. The internal cavity is filled with concrete. The evenness of the fixation is checked using a building level.

A popular type of rack is profile pipes. Eat different ways their fastening in the ground:

- butting;

- partial or complete concreting;

- concreting the well below the soil freezing level.

Ribbon-column (combined)

The most durable base for heavy fences made of brick, stone, forged and gabions. It is used in areas located on slopes, soils with increased heaving and in difficult climatic conditions.

It is called combined because it is a ribbon of concrete, in which there are separate extensions for supports.

Before construction, you need to pay special attention to the pillars. Treat metal ones from corrosion, coat wooden ones with bitumen.

Regardless of the material of the supports, before installation, it is better to wrap them in roofing material to protect them from excess moisture.

The rest of the construction order is as follows:

- A trench is dug. The depth of the foundation is determined by the type of soil, but it must be at least 50 cm. The length and width are taken in accordance with the previously developed diagram.

- Inside the trench, holes are made for pillars with a width of 40 cm and a depth of 1.5 m. The step between them is from 2 to 3 m.

- The pillars are fixed in the recesses. If necessary, spacers can be installed.

- To increase strength, reinforcement is laid around the supports and along the perimeter of the entire trench. It is better to tie it so that a continuous frame is formed.

- Concrete is poured into the recesses under the pillars.

- Along the perimeter of the trench, formwork is made of wooden boards.

- The solution is poured to the initial surface of the soil.

The reinforcement stage should be approached responsibly, since a properly assembled metal frame will protect the fence from subsidence for a long time.

Screw

It is recommended to install screw piles in regions with complex heaving soils, which expand and rise during severe frosts. Such soil gradually pushes out the pillars, which leads to deformation of the fences. Will do pile foundation areas that are on a slope.

These look like metal pipes with a blade at one end. This element serves as an anchor, thanks to which the piles are securely fastened to the ground.

3D model brick fence on screw piles

3D model brick fence on screw piles Installation is carried out below the freezing point of the soil. It will not be possible to build such a foundation yourself, since you will need special equipment and knowledge of all the nuances of installation. The sizes of piles vary, but manufacturers often make them to order.

Stone (rubble)

Set up on stable soils. It should not be used on clay soil; as layers of soil slide, it will begin to deform.

Pairs perfectly with a beautiful wrought iron or stone fence. It costs a lot. Creation is not possible for beginners. To form the foundation structure, you will have to involve a specialist. During the laying process, stones of different sizes and shapes are taken.

If the construction technology is followed, this is the most durable and reliable foundation.

Masonry is carried out using dry or liquid mortar.

Among the nuances of the arrangement it is noted that:

- Precise joining of stones is necessary. They must fit closely together, so you will need to stock up on a large number of cobblestones of different sizes to find the ones you need.

- The texture of the stones that are inside the base is not important. Attention is paid to the outer part of the structure.

- The voids around large stones are filled with small ones.

- The type of solution is determined by the master, but it has been noted that the dry mixture lasts longer than the liquid one.

On a gravel bed (monolithic)

Reinforced version of concrete tape. It is used for massive structures made of brick, concrete, forged spans, and gates.

Feature – layer-by-layer laying of gravel and sand in the trench. For reliability, the use of buta is allowed.

Work order:

The gravel cushion performs a drainage function, preventing the impact of groundwater on the structure.

Block (torn stone, besser)

A type of strip foundation. Reinforced concrete, besser blocks, and torn stone are used to create.

Besser is a relatively new type of block. It is made by pressing cement and sand. Perfectly imitates natural stone. Comes in a variety of shades.

Looks good with a fence made of brick, corrugated board, natural stone, or forging.

The width of the trench should be taken equal to the width of the two blocks.

The further order of work is as follows:

Determining the depth of the foundation

The key factors influencing this indicator are the type of soil and the topography of the site.

Clay, sandy, sandy loam soil is considered soft, while shale and rocky soil is considered hard.

To accurately determine the required depth, it is important to take into account the slope of the estate. If there are large differences in heights at the location where the fence is installed, then the depth of the foundation is different in individual areas.

A monolithic tape is suitable here, for even laying of which beacons are set. It is better to fill areas with different heights separately and make sure that the upper level of the base protrudes at least 10 cm above the ground.

On hard soils, the depth of the trench can be reduced by 10–20 cm from the usual value.

In the case of loose earth, high level The groundwater depth is increased by 15–30 cm. This will be good protection against foundation subsidence.

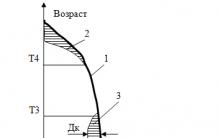

Left. Wrong way to bookmark. The foundation laid above the freezing level of the soil is pushed out by swelling forces, raising it to a height A. Right. The right way, the foundation is laid below the soil freezing level and does not experience the pressure of frozen soil. A - foundation pressure on the ground; B - soil resistance; B - buoyancy forces of soil swelling; G - tangential lateral forces; GWL - groundwater level; UGP - soil freezing level.

Left. Wrong way to bookmark. The foundation laid above the freezing level of the soil is pushed out by swelling forces, raising it to a height A. Right. The right way, the foundation is laid below the soil freezing level and does not experience the pressure of frozen soil. A - foundation pressure on the ground; B - soil resistance; B - buoyancy forces of soil swelling; G - tangential lateral forces; GWL - groundwater level; UGP - soil freezing level. On clay soil, pit trenches are made at least 15 cm below the freezing point. Due to this, the fence will not be damaged by soil heaving.

At high level If the soil freezes (over 2 m) around the fence, it is recommended to additionally build a drainage system, which reduces the groundwater level.

Experienced builders recommend not abandoning the foundation when planning the installation of permanent fencing. Even in the version of a lightweight fence, this is excellent protection against deformation, environmental influences and a guarantee of a long service life.

Carrying out an inventory

Ulyukaev, Navka and Patrushev

Income tax refund for treatment: registration procedure and calculation of the deduction amount

Import substitution - what is it?

OSAGO minimum insurance period